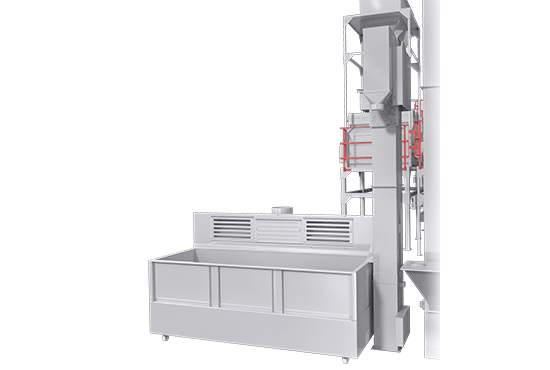

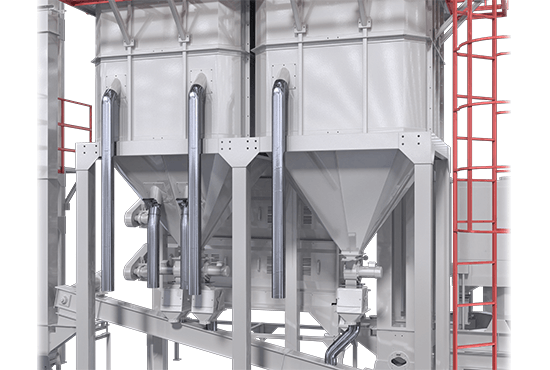

Receiving / Cleaning Section

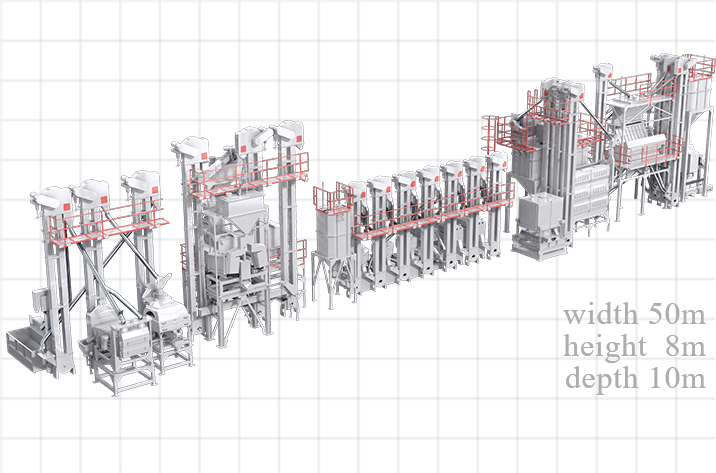

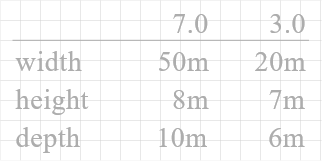

Spec

REACH SYSTEM 7.0 (Paddy input 7.0t/h)

| Q'ty | |

|---|---|

| Wide Hopper | 1 |

| Milling Separator | 1 |

| Leg Aspirator | 1 |

| Destoner | 1 |

| Ancillary Equipment |

|---|

| Bucket Elevator x3 |

| Fan x1, Cyclone x1 |

| Rotary Valve x1 |

| Control Panel x1 |

REACH SYSTEM 3.0 (Paddy input 3.0t/h)

| Q'ty | |

|---|---|

| Wide Hopper | 1 |

| Pre Cleaner | 1 |

| Destoner | 2 |

| Ancillary Equipment |

|---|

| Bucket Elevator x3 |

| Fan x1, Cyclone x1 |

| Rotary Valve x1 |

| Control Panel x1 |

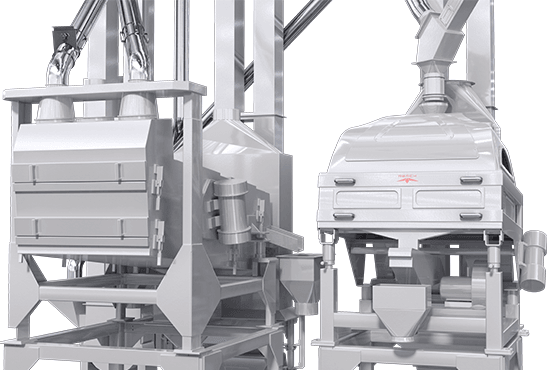

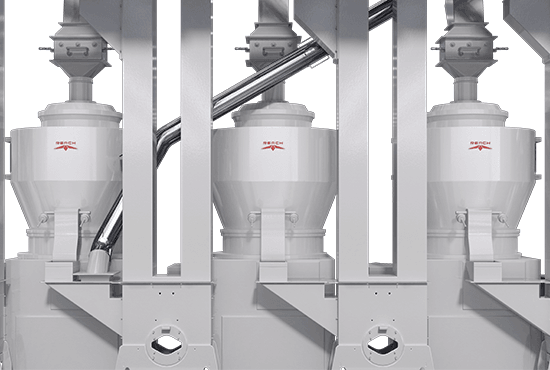

Husking / Separating Section

Spec

REACH SYSTEM 7.0 (Paddy input 7.0t/h)

| Q'ty | |

|---|---|

| Paddy Husker | 2 |

| Aspirator | 2 |

| Paddy Separator | 1 |

| Ancillary Equipment |

|---|

| Control Tank 1.5t (Paddy) x 1 |

| Control Tank 0.4t (Paddy, Brown) x 2 |

| Bucket Elevator x 3, Fan x 1 |

| Chain Conveyor x 2, Control Panel x 1 |

REACH SYSTEM 3.0 (Paddy input 3.0t/h)

| Q'ty | |

|---|---|

| Paddy Husker | 1 |

| Aspirator | 1 |

| Paddy Separator | 1 |

| Ancillary Equipment |

|---|

| Control Tank 1.2t (Paddy) x 1 |

| Control Tank 0.1t (Paddy, Brown) x 1 |

| Bucket Elevator x 3, Fan x 1 |

| Control Panel x 1 |

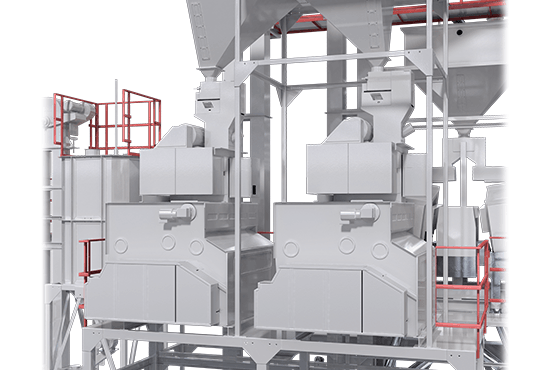

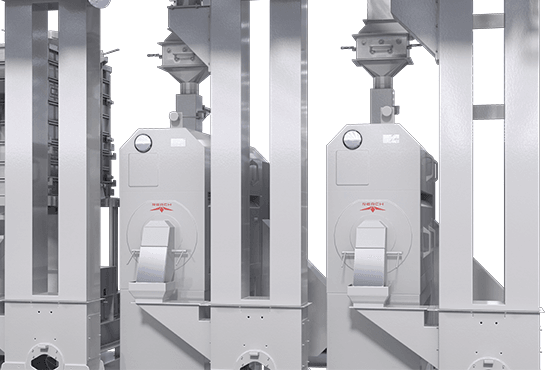

Milling / Polishing Section

Spec

REACH SYSTEM 7.0

| Q'ty | |

|---|---|

| Rice Milling Machine | 3 |

| Sifter | 1 |

| Rice Polisher | 2 |

| Ancillary Equipment |

|---|

| Control Tank 1.8t (Brown) x 1 |

| Bucket Elevator x 7 |

| Suction Fan x 1, Cyclone x 2 |

| Rotary Valve x 3, Control Panel x 1 |

REACH SYSTEM 3.0

| Q'ty | |

|---|---|

| Rice Milling Machine | 2 |

| Sifter | 1 |

| Rice Polisher | 2 |

| Length Grader | 1 |

| Ancillary Equipment |

|---|

| Control Tank 1.8t (Brown) x 1 |

| Bucket Elevator x 6 |

| Fan x 1, Cyclone x 1 |

| Rotary Valve x 1, Control Panel x 1 |

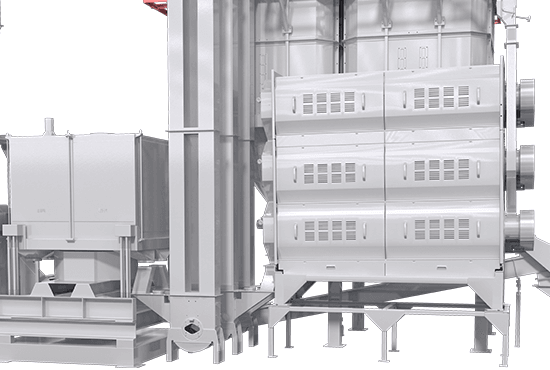

Grading /

Blending Section

Spec

REACH SYSTEM 7.0

| Q'ty | |

|---|---|

| Sifter | 1 |

| Length Grader (1) | 1 |

| Length Grader (2) | 1 |

| Mixing System | 1 |

| Ancillary Equipment |

|---|

| Bucket Elevator x 3 |

| Chain Conveyor x 1, Fan x 1 |

| Blending Tank x 2, Cyclone x1 |

| Control Panel x 1 |

REACH SYSTEM 3.0

| Q'ty |

|---|

| None |

| Ancillary Equipment |

|---|

| None |

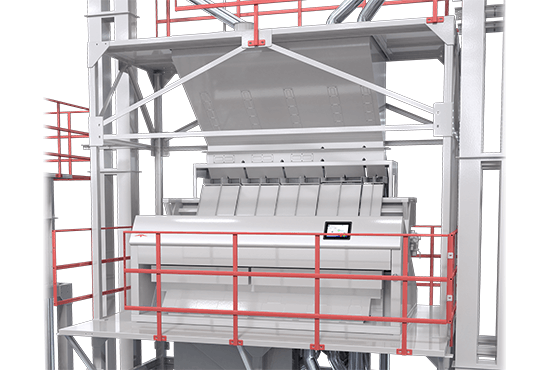

Optical Sorting Section

Full Color Optical Sorter

Detection of subtle color differences

All kinds of defects can be detected by full color camera.

High Spec CPU

Precise analysis of incoming rice

Sorting conditions are monitored by high-performance CPU for reliable operations.

Spec

REACH SYSTEM 7.0

| Q'ty | |

|---|---|

| Optical Sorter | 1 |

| Ancillary Equipment |

|---|

| Bucket Elevator x 4 |

| Control Tank 0.35t (White) x 1 |

| Fan x 1, Cyclone x 1 |

| Control Panel x 1 |

REACH SYSTEM 3.0

| Q'ty | |

|---|---|

| Optical Sorter | 1 |

| Ancillary Equipment |

|---|

| Bucket Elevator x 3 |

| Control Tank 0.1t (White) x 1 |

| Fan x 1, Cyclone x 1 |

| Control Panel x 1 |

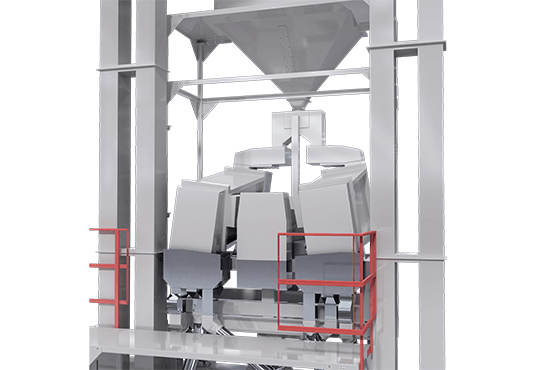

Packing Section

Scale

Load cell and micro computer

Highly accurate control by load cell and micro computer provides precise weight measurement.

Digital Display System

At-a-glance display

Weighing status is easily monitored with the digital display.

Spec

REACH SYSTEM 7.0

| Q'ty | |

|---|---|

| Packer | 1 |

| Ancillary Equipment |

|---|

| Packer Tank 3.0t (White) x 1 |

REACH SYSTEM 3.0

| Q'ty | |

|---|---|

| Packer | 1 |

| Ancillary Equipment |

|---|

| Packer Tank 0.9t (White) x 1 |

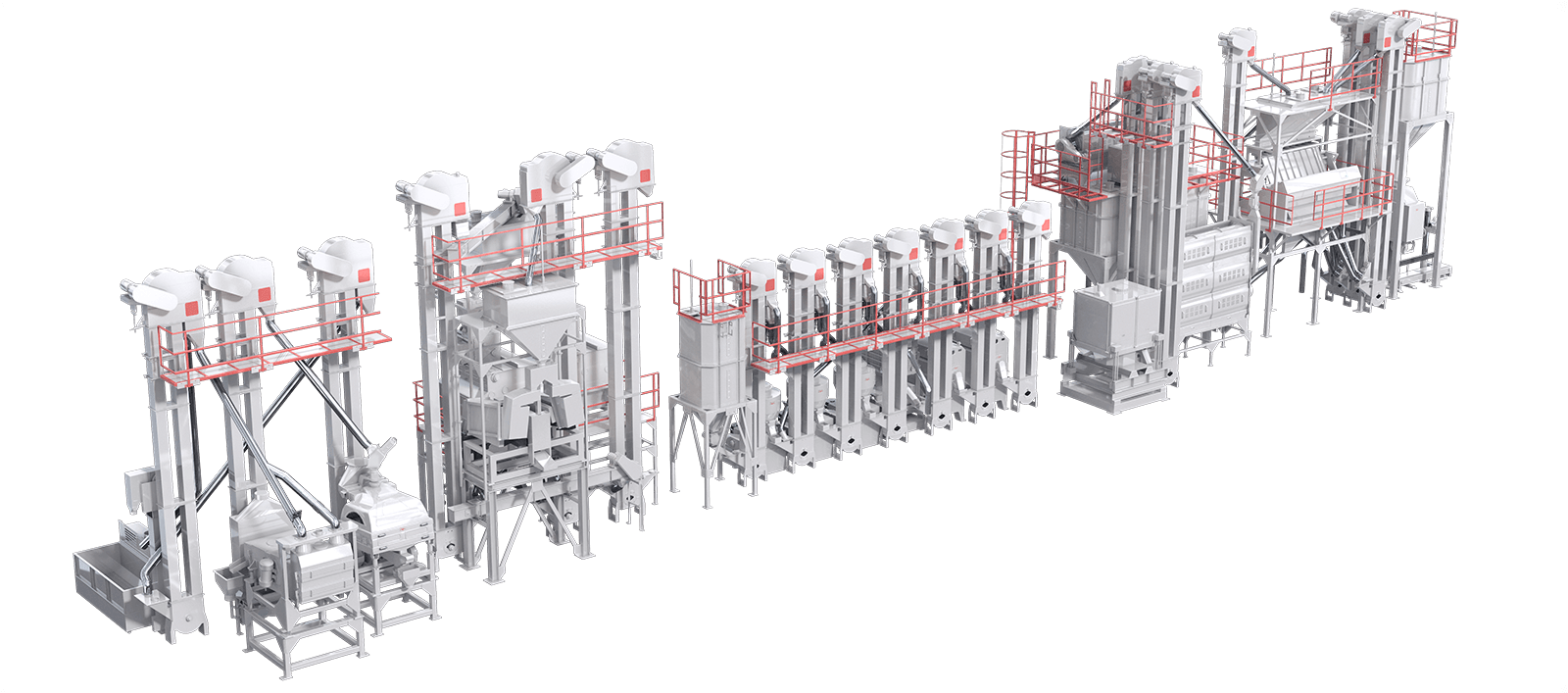

- Receiving / Cleaning

- Husking / Separating

- Milling / Polishing

- Grading / Blending

- Optical Sorting

- Packing

- Options